Do you have any questions or would you like a consultation?

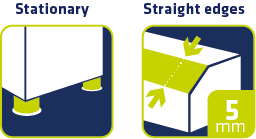

The KSM 125 and KSM 130 edge grinding machines are designed for deburring and edge cutting of small to big workpieces starting with a thickness of 2 mm. The chamfer is scrubbed and finished in one step with our two-zone grinding disc. The chamfer setting is made by opening / closing the prism. This is used effectively and efficiently through the axial adjustable corundum grinding disc.

The KSM 125 has an integrated extraction socket for connection to an extraction system. A water cooler is installed in the KSM 130. The machines are equipped with hardened and polished guide rails. Hardened workpieces and HSS materials can be processed p to 5 mm x 45° in multiple steps.

For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machines can be installed on an undercarriage for flexible use in a workshop.

| Technical data | KSM 125 | KSM 130 |

| Motor | 0,75 kW | 2.890 rpm | 0,75 kW | 2.890 rpm |

| Energy | 400 V, 50/60 Hz | 400 V, 50/60 Hz |

| Vc | 700 - 1.100 m/min | 700 - 1.100 m/min |

| Maximum chamfer width | 5 mm | 5 mm |

| Grinding disk, conical | Ø min. 80 mm, max. 125 mm | Ø min. 80 mm, max. 125 mm |

| Dimensions (LxBxH) | 640 x 300 x 400 mm | 700 x 650 x 400 mm |

| Weight | 85 kg | 85 kg |

| Item No. | 15990 | 60715 |