Do you have any questions or would you like a consultation?

The small and compact edge processing machine with sliding carriage is designed for chamfering and grinding small to medium-sized workpieces starting with a thickness of 1 mm. The light aluminium casing, the wear-resistant and sanded guide rails, the speed regulation and the optionally available extraction sockets convince in every regard.

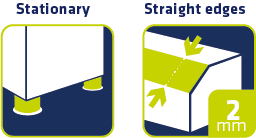

The sliding carriage protects the workpiece surface of components that are sensitive to scratches. The workpiece is inserted in the V-prism from the sliding carriage. The processing is performed by pushing the sliding carriage with workpiece over the tool. The travel path is 210 mm. The sliding carriage can be locked in place for longer components.

Our variety of high-quality solid carbide chamfers provide for vibration-free, clean and constant chamfering quality depending on the material. A chamfer width of up to 4 mm is possible in NE-metals and a chamfer width of up to 2 mm in steel. Hardened workpieces as well as components made of HSS and hard metal can be processed through optional CBN or diamond grinding discs.

We recommend an industrial vacuum with automatic switch-on for this machine so that cleanliness at the workplace can be guaranteed. This simultaneously increases the service life of the spindle. For high-alloy materials, the speed range can be adjusted for the series from 10,000 to 30,000 rpm, through a technical change, to 2,800 to 7,400 rpm. Thanks to the brushless motor the machine is perfect for continuous operation.

| Technical data | Speedy Prisma 210 - PSL |

| Motor | 0,14 kW | 10.000 - 30.000 rpm |

| Energy | 230 V, 50 Hz |

| Maximum chamfer width | 2 mm |

| Dimensions (LxBxH) | 320 x 200 x 180 mm |

| Weight | 8,5 kg |

| Item No. | 46069 |