Do you have any questions or would you like a consultation?

The sturdy chamfering machines are designed for chamfering, edge chamfering and welding seam preparation. The machines can process sheet thicknesses from 2 - 190 mm. The machines generate a very good chamfering quality thanks to the optimized interaction between the cutter head, cutting inserts and minimal quantities of lubrication.

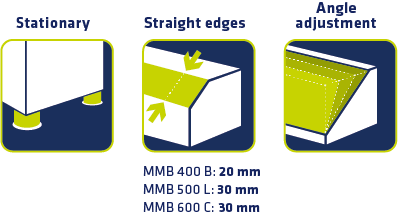

In NE-metals and steel, a chamfer width up to 30 mm is possible. The MMB machines have gradual speed regulation, which is very useful when processing aluminum or stainless steel. The angle adjustment can be set gradually in the range of 30° depending on the machine type and design, for example, 25 - 55°, 30° - 60° or 35 - 65°.

The MMB series is equipped with a feed unit by default. The machines can be extended with roller guide ways or converted into automatic chamfering machines. Depending on the design, the machine table is equipped with ball or heavy-duty rollers.

| Technical data | MMB 400 B | MMB 500 L | MMB 600 C |

| Motor | 5,5 kW | 2.000 - 6.000 rpm | 7,5 kW | 2.000 - 6.000 rpm | 7,5 kW | 2.000 - 6.000 rpm |

| Energy | 400 V, 50/60 Hz | 400 V, 50/60 Hz | 400 V, 50/60 Hz |

| Maximum chamfer width | 20 mm | 30 mm | 30 mm |

Angular adjustment | 25° - 55° / 30 - 60° / 35° - 65° | 20° - 50° / 25 - 55° / 30° - 60° | 20° - 50° / 25 - 55° / 15° - 60° (Digital display) |

| Maximum work piece thickness | 2 - 100 mm | 5 - 100 mm | 5 - 190 mm |

| Dimensions (LxBxH) | 900 x 1.500 x 1.800 mm | 1.510 x 1.490 x 1.750 mm | 1.490 x 1.520 x 1.830 mm |

| Tabletop (LxB) | 750 x 490 mm | 1.490 x 700 mm | 1.490 x 700 mm |

| Weight | 540 kg | 770 kg | 1.050 kg |

| Item No. | 69203 | 62871 | 70985 |