Do you have any questions or would you like a consultation?

ENTMAG tunnel demagnetizers allow for a simple and quick demagnetizing of ferrous small and large parts.

The workpiece is moved through the inner space of the tunnel by hand, chute or free fall.

Demagnetizing is terminated only after leaving the plate at a distance of appr. 300 mm. The workpieces are recommended to be demagnetized one by one. Clusters are to be avoided.

This is a durable, moisture-protected installed device with a steel casing. The demagnetizers are made upon customer request and are available in all operating voltages and frequencies. A lower frequency or pulse frequency will be used if there are problems. This may result in switch-on durations between 80 - 100%. Demagnetization can penetrate deeper than 0.5 mT (5 Gauss).

We recommend type 163 for workpiece made of unalloyed, soft steel. Type 164 with reinforced coil should be used for treated or alloyed workpiece steel.

Why demagnetizing?

All the ferrous and ferromagnetic materials are capable of creating magnetic zones. This may occur with the raw material storage, with magnetic crack and hardness tests, cold forming, chip cutting, measuring or magnetic clamping and lifting.

Basically, magnetism is not harmful, but may prove interfering with further processing.

While demagnetizing, the magnetic field in the workpiece gets neutralised. The workpiece is magnetically neutral. The demagnetizing effect can be obtained by intense heating or a very strong external magnetic field. After demagnetization, the magnetic forces in the workpiece have disappeared. The magnetic field can be restored through remagnetization.

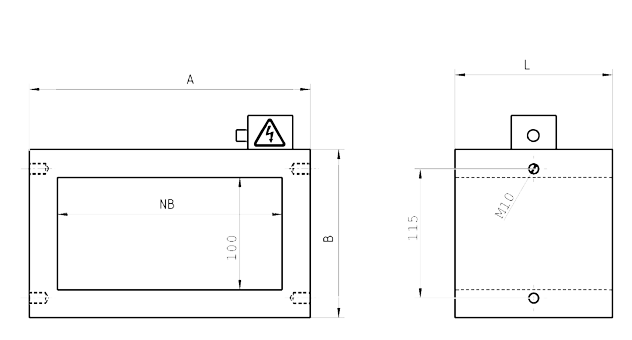

| Technical data | Dimensions [H x NB x L x A x B] | Weight | Item No. |

| [mm] | [kg] | ||

| T163 | 100 x 200 x 140 x 300 x 190 | 16 | 64153 |

| T163 | 100 x 400 x 140 x 500 x 190 | 24 | |

| T163 | 150 x 400 x 190 x 500 x 240 | 34 | 64181 |

| T164 | 100 x 200 x 140 x 320 x 210 | 29 | |

| T164 | 100 x 400 x 140 x 520 x 210 | 45 | 62592 |

| T164 | 150 x 400 x 190 x 520 x 260 | 59 | 65157 |